EcoNautic Systems GmbH

Brauereistraße 15

D-17159 Dargun

Tel.: +49 39959 251-0

Fax: +49 39959 251-10

Verstellringe

Verstellringe - Einzelteil für Turbolader

Button

Bildtitel

Brennkammern - Einzelteil für Airbags

Button

Bildtitel

Verschraubung - Einzelteil für Gasturbinen

Button

Bildtitel

Segment - Einzelteil für Gasturbinen

Button

Bildtitel

Umlenkkammer - Einzelteil für Gasturbinen

Button

Bildtitel

Kappe - Einzelteil für Gasturbinen

Button

Bildtitel

Flansch - Einzelteil für Gasturbinen

Button

Bildtitel

Gehäuse - Einzelteil für Gasturbinen

Button

Bildtitel

Flansch mit Stutzen - Baugruppe für Gasturbinen

Button

Bildtitel

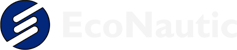

Zünderstutzen - Baugruppe für Gasturbinen

Button

Bildtitel

Grundkörper - Baugruppe für Gasturbinen

Button

Bildtitel

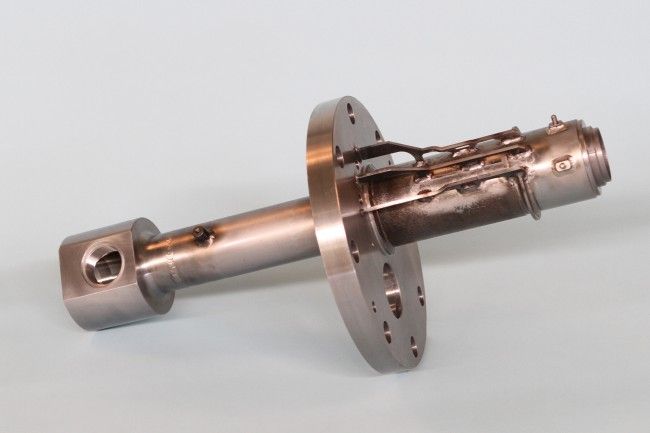

Brennerträger - Baugruppe für Gasturbinen

Button

Bildtitel

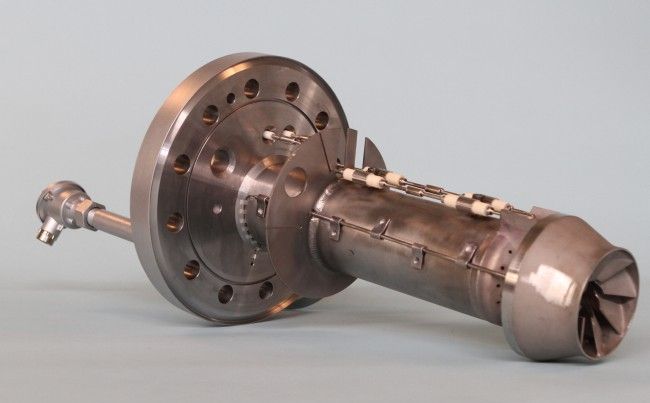

Messelement - Einzelteil für industrielle Wägetechnik

Button

Bildtitel

Messelement - Einzelteil für industrielle Wägetechnik

Button

Bildtitel

Ventilgleiter - Einzelteil für Mobilhydraulik

Button

Bildtitel

Hebel - Einzelteil für Flugzeugturbinen

Button

Bildtitel

Gasführungrohr - Einzelteil für Gasturbinen

Button

Bildtitel

Abtriebsflansch - Einzelteil für Nutzfahrzeuge

Button

Bildtitel

Zahnkranz - Einzelteil für Nutzfahrzeuge

Button

Bildtitel

Buchse - Einzelteil für Nutzfahrzeuge

Button

Bildtitel

Polrad - Einzelteil für Nutzfahrzeuge

Button

Ihr kompetenter Partner für spanabhebende Fertigung in der Mecklenburger Schweiz

Seit mehr als 50 Jahren arbeitet die EcoNautic Systems GmbH als angesehener Qualitätszulieferer mit weltweit agierenden Konzernen zusammen.

EcoNautic fertigt mehr als 200 verschiedene Produkte und Schweißbaugruppen gemäß Kundenspezifikationen bzw. Kundenzeichnungen aus allen zerspanbaren Werkstoffen. Die CNC-Bearbeitung von Verstellringen für Turbolader, Brennkammern für Airbags und Schweißbaugruppen für Gasturbinen sind Bestandteil unseres Lieferprogramms.

Profitieren auch Sie von unseren Fachkenntnissen und entscheiden Sie sich für die EcoNautic Systems GmbH als Ihren Zulieferer.

Einen weiteren Einblick über unser Unternehmen erhalten Sie in diesem Video über den Besuch der Ministerpräsidentin Manuela Schwesig im August 2023 auf dem Betriebsgelände

Hier finden Sie uns

Kontaktdaten